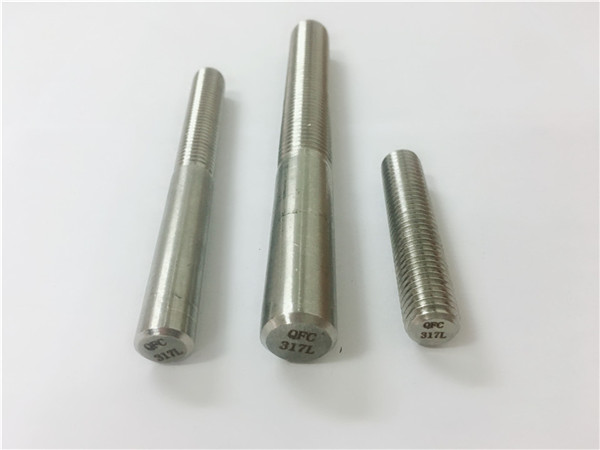

Manufacturer Special Fasteners hastelloy c276 stud bolts

Can Be Produced To Customer Drawings

American (ASME, ANSI) Standard

Size Ranges M3 to M64

No Tapers

Products can be produced to customer drawings or the relevant British (BS), American (ASME, ANSI), European (DIN, UNI) or International Standards (ISO).

The size ranges M3 to M64 Metric and 3/16" to 2.1/2" Imperial can be supplied. Thread forms include UNC, UNS, UNF, BSW, BSF, Whitworth, Metric, Metric Fine.

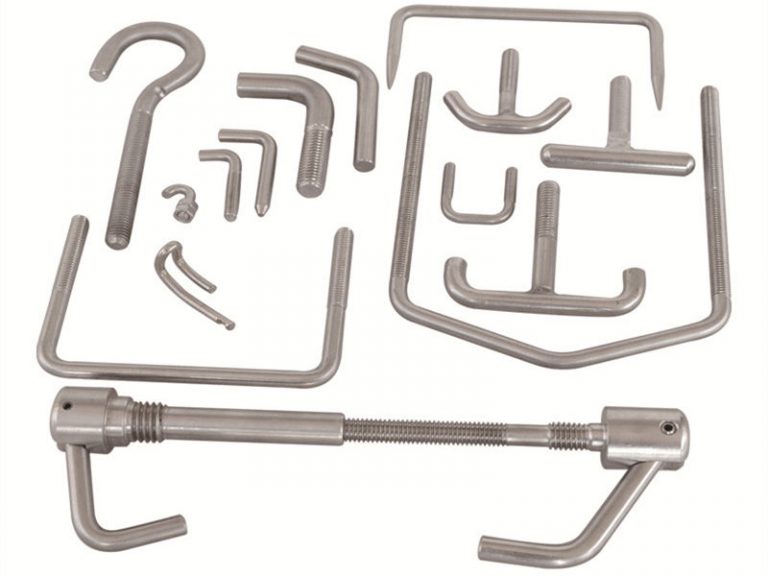

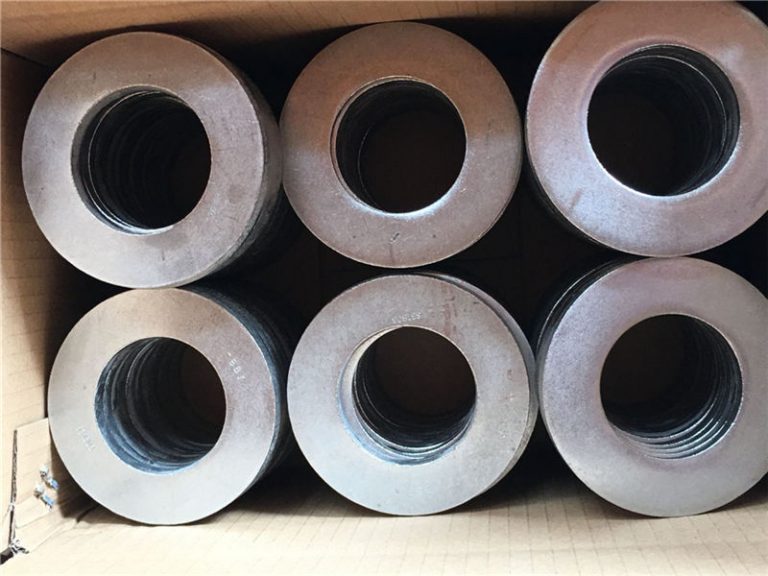

Studbolts/Studs/Studding. Studbolts can be supplied in cut lengths and Studding in full bar lengths upto 4 metres long. Din 975, Din 976, BS4882, BS4439, Din 938, ANSI/ASME B16.5. Special machined components, like bobbins or crossbars.

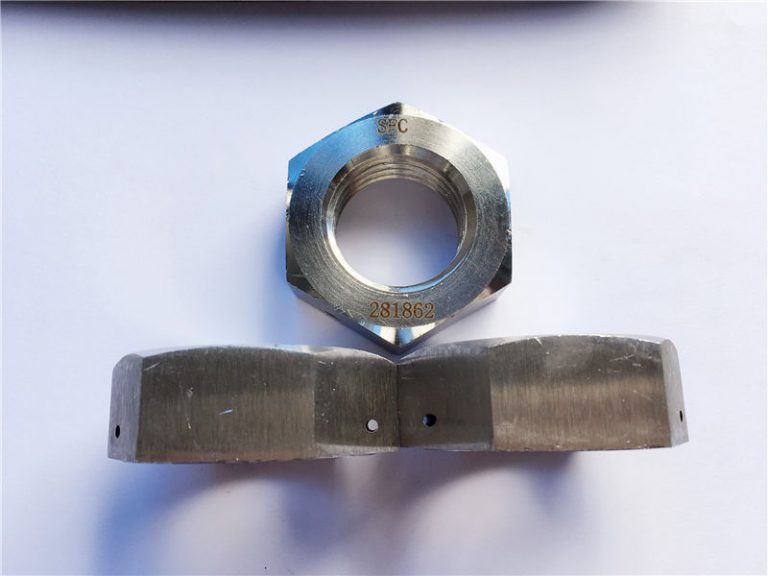

Hexagon Nuts/Lock Nuts/Nyloc Nuts, Din 934, Din 439, Din 985, Din 980, BS3692, BS1769, BS1768, BS1083, ISO 4032.

Socket Capscrews/Socket Countersunk Screws/Socket Setscrews. BS4168, BS2470, Din 912, ANSI/ASME B18.3, ISO 4762.

Hastelloy C-276 Chemical composition

Alloy | % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S |

C | Min. | balance | 14.5 | 15 | 4 | 3 | |||||||

Max. | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.08 | 1 | 1 | 0.35 | 0.04 | 0.03 | ||

C276 | Min. | balance | 14.5 | 15 | 4 | 3 | |||||||

Max. | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.35 | 0.04 | 0.03 |

Hastelloy C-276 Physical properties:

Density | 8.9 g/cm³ |

Melting point | 1325-1370 ℃ |

Hastelloy C-276 Alloy m inimum mechanical properties in the room temperature

Alloy state | Tensile strength Rm N/mm² | Yield strength R P0. 2N/mm² | Elongation A 5 % |

C /C276 | 690 | 283 | 40 |

Characteristic as below

1.Excellent corrosion resistance to most of corrosion media in oxidation and reduction environments.

2.Excellent resist pitting, crevice corrosion and stress corrosion cracking performance.

Hastelloy C-276 Metallurgical structure

C276 is face-centered cubic lattice structure.

Hastelloy C-276 Corrosion resistance

C276 alloy suit for many kinds of chemical process industry which contain the oxidizing medium and reductant. High molybdenum and chromium content make it can resist the chloride corrosion, and tungsten make it corrosion resistance better.C276 is one of a few material that can resist the corrosion of most chlorine, hypochlorite and chlorine dioxide, this alloy have prominent corrosion resistance to high concentration chlorate( iron chloride and copper chloride).

Hastelloy C-276 Application field:

C276 is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system.This material especially suit for high temperature environment, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environment.

Hastelloy C-276 Other application field:

1. The digester and bleacher in the use of paper pulp and paper making industry.

2.Absorption tower, re-heater and fan in the FGD system.

3. The equipment and parts in the use of acidic gas environments.

4. Acetic acid and anhydride reaction generator

5. Sulfur acid cooling

6.MDI

7.Manufacture and processing of impure phosphoric acid.